Mastering Cost and Value Management Across Product Lifecycle

Cost and value management is rising on the executive agenda as supply chains face persistent cost pressures and market volatility. Today, 45% of companies experienced supply chain disruptions due to geopolitical tensions, with U.S.–China trade restrictions and tariffs cited as primary triggers. At the same time, operating costs continue to rise: manufacturers in the U.S. saw a 30% increase in input costs between 2021 and 2025.

Companies are under pressure to accelerate product development, redesign global footprints, and meet profitability targets. Leading firms report having reduced development cycles by up to 25% through integrated cost engineering and digital R&D approaches. These changes require coordinated action across product design, procurement, manufacturing, and after-sales.

At the heart of effectively navigating these complexities lies the strategic discipline of Cost and Value Management (CVM). In this article, we will delve into how organizations can use cost and value management across the product lifecycle to build efficiency, protect margins, and maintain competitiveness.

What Is Cost and Value Management?

A Strategic Discipline Beyond Cost Reduction

Cost and value management is not about blanket cost cuts. It links cost transparency with functional value across the product lifecycle. The goal is to reduce avoidable expenses without sacrificing what matters to the customer or the business. This means managing costs from concept to end-of-life while keeping product value and differentiation intact.

Rather than chasing savings in isolated functions, cost and value management align decisions across engineering, procurement, operations, and commercial teams. It gives organizations a framework to meet margin targets without eroding customer value.

Cross-Functional Integration

Cost and value management requires shared ownership:

- R&D teams shape product cost early through design choices

- Manufacturing drives efficiency by reducing process waste and optimizing resource use

- Procurement plays a critical role in material selection and supplier collaboration, especially as price volatility and component lead times rise

A coordinated approach across these functions enables cost control without delays, rework, or functional trade-offs. This cross-functional execution is what turns cost and value management from a theory into day-to-day practice.

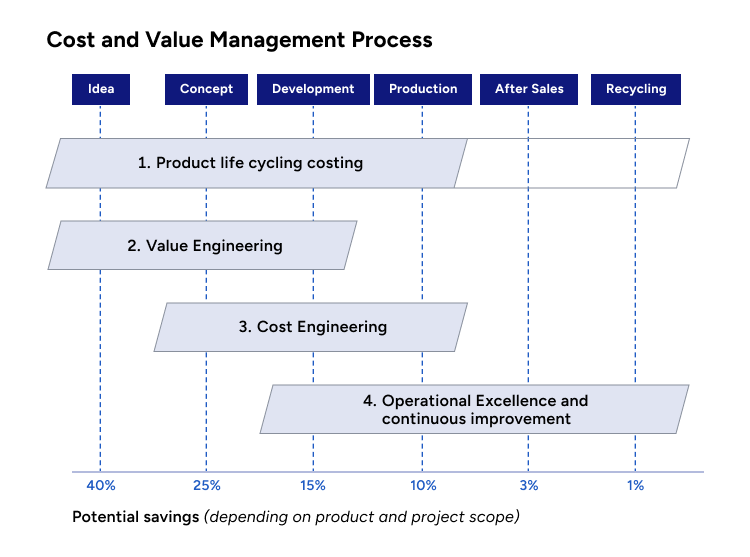

Four Levers of Cost and Value Management

Cost and value management relies on four core disciplines applied across the entire product lifecycle. These levers work best when used together, from the initial idea to the end-of-life phase:

- Product Lifecycle Costing (PLC)

- Value Engineering (VE)

- Cost Engineering (CE)

- Continuous Improvement & Operational Excellence (CI/OE)

Each lever targets a different phase of value and cost control: PLC builds a full view of lifetime cost; VE focuses on function-for-cost trade-offs; CE anchors product design to target margins; CI/OE ensures ongoing efficiency in execution.

Applying these four levers in a coordinated way, from concept through manufacturing, after-sales, and recycling, enables companies to manage costs proactively, not reactively. Understanding when and how to apply each lever is key to making cost and value management work in practice.

1. Product Lifecycle Costing (PLC)

Product Lifecycle Costing adopts a comprehensive, cradle-to-grave perspective on cost management. It entails the systematic calculation, tracking, and analysis of all costs associated with a product throughout its entire existence, encompassing every stage from its initial conception to its final disposal or recycling. It gives companies a full view of total economic impact and supports better decisions at each stage.

Why Early Design Decisions Matter

A critical aspect of PLC is understanding the relationship between the ability to influence costs and the cost of changes as the product lifecycle progresses. The potential to significantly impact costs is highest during the design phase.

Conversely, as the product moves through the product life cycle, the influenceable cost impact shrinks considerably, while the cost of implementing changes rises.

Embedding PLC into PLM Systems

A key lever in Product Lifecycle Costing is the highly iterative "concept-to-cost" or "design-to-cost" approach. This methodology links cost implications to specific design choices or modifications, providing a clear calculation of their potential impact.

This involves multiple cost drivers, including but not limited to material costs, process costs, investment costs, and footprint/network costs. For the long-term sustainability of Product Lifecycle Costing, it is important to anchor pre-product development costing principles into the organization's Product Lifecycle Management (PLM) framework, establishing the right structures and processes.

PLC also accounts for costs beyond manufacturing. It includes expenses tied to sales, service, and end-of-life processing. This broader view helps identify risks and savings across the full value chain.

2. Value Engineering (VE)

Value Engineering is a systematic and creative problem-solving methodology focused on improving the “value” of a product, service, or process. Value, in this context, is defined as the ratio of function to cost.

The primary objective of Value Engineering is to enhance the essential functions required to meet customer needs while simultaneously reducing the total cost of ownership.

Prioritizing Functions That Matter

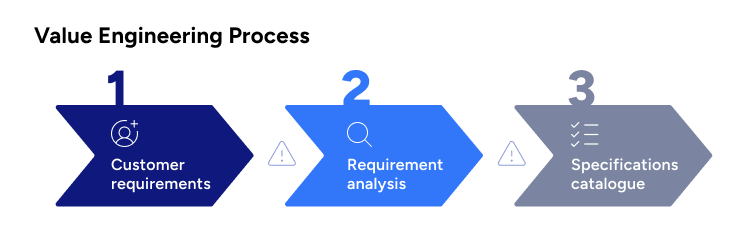

Value Engineering places a strong emphasis on understanding and prioritizing customer requirements. The process typically follows a structured approach: first, a deep dive into customer needs, followed by a thorough requirements analysis, culminating in a detailed specifications catalogue.

A core purpose of VE is to strike the right balance, ensuring that there is no "over-engineering" (where features or performance exceed customer needs and drive up unnecessary costs and therefore prices), and equally avoiding "under-engineering" (where essential functionalities are lacking, leading to customer dissatisfaction).

Value Engineering also helps reduce complexity. By mapping common functions across product variants, companies can identify which features add value and which do not. This supports modular design and standardization, and tools like value driver trees and benchmarking help quantify trade-offs. Besides cost, the analysis considers how features support pricing, differentiation, and willingness to pay.

Maximizing Design Flexibility Early

Value Engineering is most effectively applied during the early stages of the product lifecycle. At this juncture, there is maximum flexibility to influence the design and specifications of a product before significant investments are made in tooling and production processes.

By rigorously analyzing the required functions and exploring alternative materials, designs, and processes, Value Engineering teams can identify opportunities to enhance the cost-to-benefit ratio without compromising performance, reliability, or quality.

3. Cost Engineering

Target Costing as the Anchor

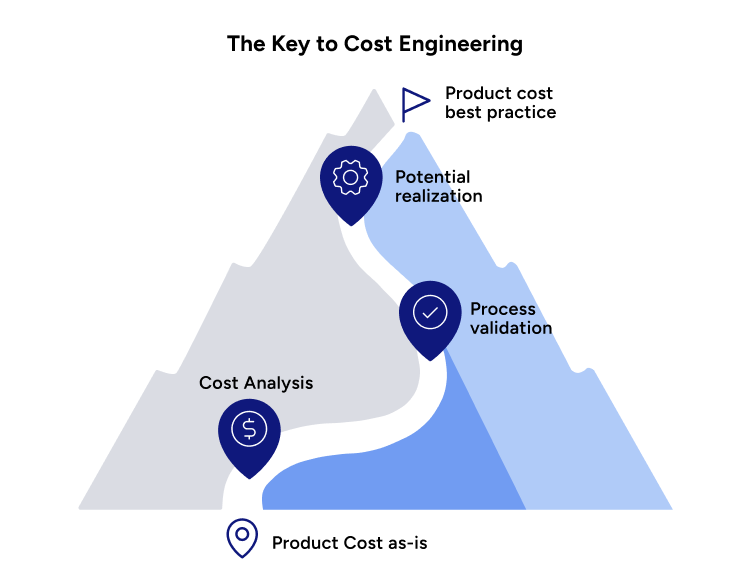

Cost Engineering applies engineering principles and practices to the estimation, planning, and control of costs throughout the project and product lifecycles. A key methodology within Cost Engineering is Target Costing, where a desired selling price minus a profit margin leads to the allowable target cost for the product.

Once the target cost is set, engineering, procurement, and design teams work together to meet it. Decisions on materials, components, and manufacturing processes are aligned with that cost ceiling. This is especially important in price-sensitive markets, where margin pressure limits flexibility.

Target costing prevents late-stage cost overruns by setting clear financial limits from the start. It makes cost management a design task, not a downstream correction.

Refining Costs Through Collaboration

Early-stage cost models provide guidance on feasibility and help filter concepts before time and money are spent. As the product matures, cost engineering supports trade-off decisions, evaluating alternatives for cost, risk, and manufacturability.

This includes refining estimates for tooling, sourcing, and process options. The goal is to prevent late changes by embedding cost control into design from the outset.

4. Continuous Improvement and Operational Excellence (CI/OE)

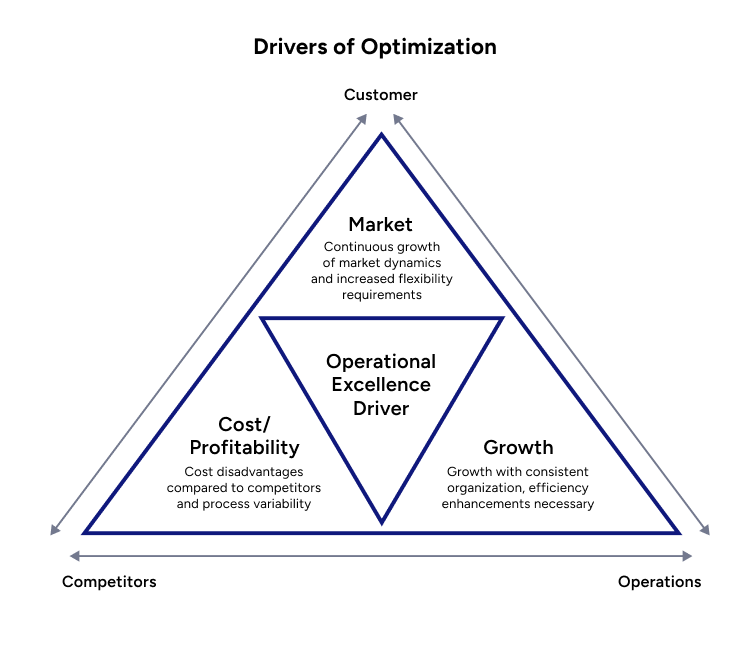

Continuous Improvement (CI) is the engine that drives an organization towards Operational Excellence (OE), characterized by the pursuit of lean and virtually waste-less operations.

This involves a deep commitment to minimizing the consumption of time, resources (materials, energy, capital), and effort while maximizing efficiency and focus on value creation. The goal is to establish sustainable practices that consistently deliver superior outcomes with minimal internal friction and loss.

Across the product lifecycle, this internal focus on lean operations is paramount in the Development, Manufacturing, After-Sales, and End-of-Life/Recycle stages. In the Development phase, Continuous Improvement aims to optimize the development process itself, reducing lead times, eliminating unnecessary steps, and ensuring efficient allocation of engineering resources to bring products to market faster.

Lean Manufacturing in Action

The Manufacturing stage is where the pursuit of lean operations through CI/OE takes center stage. Methodologies like Lean Manufacturing are directly focused on identifying and eliminating waste.

This includes direct interventions on the shop floor to reduce setup times, rebalance lines, and optimize labor and machine use. CI/OE initiatives that involve physical production areas often generate fast, measurable impact when supported by real-time data and hands-on coaching.

Optimization Beyond Production

In the After-Sales phase, CI/OE efforts are directed at optimizing service delivery processes to minimize response times, reduce the need for rework or repeat service calls, and ensure efficient utilization of service personnel and spare parts inventory. The focus is on creating lean service operations that deliver high customer satisfaction with minimal internal resource drain.

Finally, at the End-of-Life/Recycle stage, CI/OE drives the internal optimization of processes related to product take-back, disassembly, and recycling. The aim is to minimize the time and resources required for these processes while maximizing material recovery and reducing environmental impact in an efficient and cost-effective manner.

Business Impact and Benefits of Cost and Value Management

Achieving Operational Excellence through Continuous Improvement requires an organizational culture that empowers employees to identify and eliminate organizational complexity and waste, encourages experimentation and learning, and prioritizes data-driven decision-making to continuously refine internal processes towards a state of leanness and efficiency.

Implementing comprehensive Cost and Value Management yields significant benefits for organizations and their customers. These include:

- Reduced costs and improved profitability: By actively managing costs at every stage

- Enhanced product value and customer satisfaction: By focusing on delivering the required functions efficiently

- Increased operational efficiency and reduced waste: Through optimized processes and continuous improvement

- Faster time-to-market for new products: By integrating cost and value considerations early in the development cycle

- Stronger competitive advantage: By offering superior value at competitive prices

- Improved decision-making: Based on a thorough understanding of cost and value drivers

From Strategy to Execution: Managing CVM Projects

Effective cost and value management depends not only on technical methods but also on disciplined project execution and change management. The diagram below illustrates the dual approach required: structured project management using the Plan-Do-Check-Act (PDCA) cycle, and the parallel need for change enablers such as top management commitment, cross-functional collaboration, and process ownership.

- Plan: Analyze current state and define target cost/value levers

- Do: Pilot solutions in specific products, plants, or teams

- Check: Organize teams, train key functions, and evaluate impact

- Act: Scale what works across functions and product lines

Embedding these steps into cross-functional cost transformation programs ensures cost and value management is sustained, not just initiated.

Conclusion

The true power of Cost and Value Management lies in the synergistic application of these four levers across the entire product lifecycle. Product Lifecycle Costing provides the overarching framework for understanding the total economic impact, while Value Engineering optimizes value, and Cost Engineering reduces costs.

Continuous Improvement and Operational Excellence drive efficiency and cost control in manufacturing and ongoing optimization throughout the product's existence. This integrated approach ensures that cost and value considerations are embedded in every decision, leading to more competitive and profitable products.

Consultport supports clients across all cost and value management levers, including design-to-cost, target costing, and cost-down initiatives in R&D, manufacturing, procurement, and logistics. We optimize processes through Business Process Management and product portfolio analysis, and deliver results through hands-on lean projects, shop floor execution, and master data utilization.

Want to know more? Find a consultant.

on a weekly basis.