Procurement Automation: From Digitalisation to Intelligent Orchestration

Over the past decade, most organisations have completed the headline task of procurement automation by making their documentation electronic. Today, over 80% of large enterprises use digital procurement tools, with global e-procurement transactions surpassing $1 trillion in 2022. As of early 2025, 91% of business buyers prefer to conduct procurement online, and 47% of procurement managers expect larger budgets for digital systems.

Purchase orders are raised in enterprise resource planning (ERP) suites, catalogues are stored in self-service portals, and invoices arrive in structured formats. Top-performing organizations approve 98% of POs electronically, while manual invoice entry into ERP systems has fallen to 60%, down from 85% in 2023.

Digitalisation in procurement, once a strategic differentiator, has become a hygiene factor. As margins tighten and supply chains grow more volatile, the boardroom conversation moves decisively from digital to automated. Executives now ask: How can we orchestrate end-to-end source-to-pay (S2P) activities with minimal human touch while preserving commercial judgment?

After 25 years leading industrial procurement functions on four continents, I see process automation as the single most potent lever for resilience, compliance, and sustainable value creation. Building on Consultport’s latest article on AI in procurement, this article outlines the evolution from digitisation to intelligent orchestration and offers a practical roadmap to help leaders unlock speed, compliance, and resilience through automation.

From Linear Digitisation to Closed-Loop Procurement Automation

Digitisation converts paper into data; automation converts data into action. In traditional linear workflows, each downstream actor awaits hand-offs from the previous step.

Automated frameworks, by contrast, operate as closed loops: data from upstream purchasing triggers downstream logistics, finance, and supplier engagement in real time, while embedded analytics feed back optimisation signals.

This paradigm eliminates the “white-space” delays that proliferate when processes are merely electronic but still manually queued. Crucially, automation does not remove people from the loop; it reallocates their capacity to strategic tasks such as category innovation and supplier-enabled sustainability. Let’s explore the main learnings to introduce procurement automation in your organization.

A Business Process Imperative – Not an IT Side Project

Because automation inevitably employs robotic process automation (RPA), artificial intelligence (AI), or low-code workflow engines, many stakeholders mislabel the journey as an IT initiative.

In reality, technology is the consequence of well-designed processes, not the cause. When organisations start with a technology lens, they risk codifying yesterday’s inefficiencies in tomorrow’s bots.

I therefore sponsor procurement automation by positioning IT as an enabling partner rather than the primary owner. This governance choice accelerates delivery because business users – the process custodians – are accountable for defining value, setting key performance indicators (KPIs), and validating outcomes.

Process Mining: Seeing Reality before Re-engineering It

No process can be automated unless it is truly understood. While traditional workshops capture what teams think happens, process mining reveals what flows daily in the ERP backbone.

My team deploys SAP Signavio Process Intelligence to visualise actual purchase-to-pay (P2P) variants, pinpoint the root causes of manual rework, and quantify automation potential in euros rather than anecdotes. By grounding automation roadmaps in facts, not assumptions, organisations neutralise endless debates and ensure each bot addresses genuine value leaks, not legacy workarounds.

Designing the Future-State Procurement Automation Architecture

A mature procurement automation architecture unites four layers:

Process Orchestration

The digital backbone that sequences tasks, routes approvals and enforces segregation-of-duties rules. Modern ERPs such as SAP S/4HANA now embed low-code workflow builders that allow business analysts to configure flows without heavy development queues.

Cognitive Services

Machine-learning models that classify spend, predict demand or flag supplier-risk events. Deployed judiciously, these capabilities elevate category managers from reactive sourcing to proactive value engineering.

Integration APIs

Lightweight connectors linking customer, supplier, and third-party data pools. Open APIs replace brittle point-to-point middleware, enabling real-time collaboration around order status, quality metrics, and carbon footprints.

Experience Layer

Chatbot and mobile interfaces that surface insights at the moment of need, empowering requisitioners and executives alike.

By aligning these layers to the purchase-to-pay journey, organisations avoid the trap of creating isolated “islands of automation” and instead build a coherent fabric that can flex with evolving business models.

dThe Leadership Dimension: Building a Seamless Procurement Experience Layer

Tools accelerate transformation, but people transform. One of the most persistent challenges in procurement change programs is not technical; it’s behavioural. Many organizations still reward tactical firefighting over process discipline, which can undermine automation efforts.

To drive sustainable change, leadership should define and communicate a clear operational standard: We pay suppliers on time, buy on contract, and leverage data to challenge demand. According to McKinsey, companies with strong procurement governance frameworks achieve 20–40% higher compliance rates in sourcing and payment processes.

Embedding these expectations into performance metrics is critical. High-performing teams track procurement automation-driven cycle-time improvements with the same rigour as cost savings and working capital impact.

In parallel, rotating high-potential procurement professionals into cross-functional automation squads strengthens ownership. Research shows that involving end users in solution design can increase digital tool adoption by up to 2.6 times. This grassroots engagement ensures that automation initiatives are anchored in business needs and continue to deliver value beyond go-live.

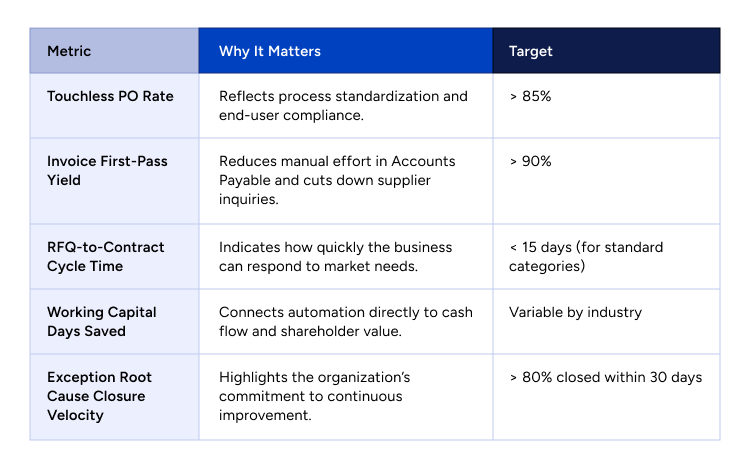

Measuring What Matters: Executive-Level Metrics for Automation Dashboards

Procurement automation programs often get lost in a sea of metrics. To keep the focus on what truly drives business value, I recommend tracking five key metrics that resonate with executive leadership:

- PO Rate

- Invoice First-Pass Yield

- RFQ-to-Contract Cycle Time

- Working Capital Days Saved

- Exception Root Cause Closure Velocity

By aligning automation success with these business outcomes, leadership can track value realization without getting lost in technical details.

The Strategic Frontier – Autonomous Procurement

Looking ahead, automation will evolve from rule-based orchestration to autonomous decision-making. Large-language models can already draft category strategies by synthesising market indices, ESG disclosures, and internal demand forecasts.

When coupled with real-time process diagnostics, these models will recommend optimal sourcing events, negotiate contract clauses within guardrails, and propose supplier innovations aligned with corporate sustainability goals. The future CPO will therefore act less as Chief Negotiator and more as Head of Value Algorithms, curating the governance, data, and ethics that shape machine-generated decisions.

Recommendations for Executive Action

#1 Anchor Automation in Corporate Strategy

Position procurement automation alongside growth and sustainability objectives, not as a cost-saving project.

#2 Invest in Master Data Organization-Wide

Create an enterprise data stewardship model and enforce it through performance incentives.

#3 Adopt Process Mining Early

Deploy tools such as SAP Signavio to ground discussions in empirical evidence, avoiding analysis paralysis.

#4 Pilot, Prove, Scale

Start with a high-volume, low-complexity workflow (e.g., indirect POs), prove value within 90 days, then scale horizontally.

#5 Upskill Procurement Talent

Blend category expertise with data literacy; make automation ownership a recognised career accelerator.

#6 Measure Outcomes, Not Activity

Report cycle-time, compliance, and working capital impact at the board level; relegate bot-runtime metrics to the delivery team.

Case Study – Procurement Automation for Market-Driven Efficiency

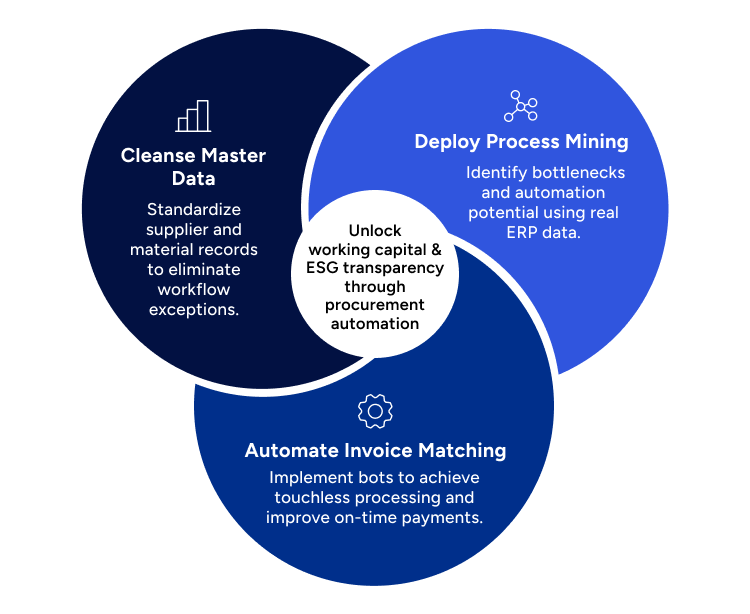

A listed manufacturing group undergoing strategic transformation engaged Consultport to improve working capital performance, reduce compliance risk, and prepare for increasing ESG disclosure requirements. The company faced major inefficiencies in its procure-to-pay (P2P) process, with 72% of workflow exceptions traced to inconsistent or incomplete master data.

Master Data — The Unseen Critical Path

In every automation initiative I have sponsored, master data has proven to be the single biggest source of avoidable complexity. In practice, up to 70% of workflow exceptions can trace back to missing or duplicated supplier records, misaligned payment terms, or inconsistent material master hierarchies.

Many companies underestimate this: they treat master data as housekeeping. In reality, it is the control tower for reliable automation. Without clean foundations, RPA scripts accelerate mistakes instead of removing them.

Prioritising a dedicated data remediation sprint before writing the first line of bot code is not optional; it is the best insurance for high-touchless rates and resilient compliance. This groundwork enabled a broader procurement automation initiative. Leveraging Signavio-powered process mining, master-data cleansing, and bot-driven invoice matching, the organisation significantly increased its touchless invoice rate, boosting efficiency and freeing the AP team to focus on dynamic discount capture rather than manual troubleshooting. Put simply, robust master data is the silent enabler behind every sustainable automation success story.

Beyond immediate process gains, the board saw clear capital market benefits: enhanced spend transparency, faster Scope 3 emissions reporting, and improved on-time payment performance contributed to a more robust credit outlook. This underlines a simple truth: when procurement automation is designed around clean data and real workflows, it becomes a lever for enterprise value, not just back-office efficiency.

Want to know more? Procurement automation goes beyond traditional sourcing and extends to how organizations engage external experts and freelancers. A Freelance Management System (FMS) automates freelance sourcing, contracting, approvals, and spend visibility, significantly reducing manual effort. See how Consultport’s Freelance Management System (FMS) enables scalable and automated freelance procurement.

Conclusion: Procurement Automation as a Leadership Mandate

Procurement stands at a pivotal juncture. The tactical digital enablement of the 2010s delivered efficiency, but it did not fundamentally redefine how value is created.

Automation, underpinned by robust master data and process intelligence, offers the next performance S-curve, one measured in strategic agility, risk resilience, and shareholder confidence. Yet technology alone will not get us there. Leadership must champion a business-first, process-centric philosophy, empowering multidisciplinary teams to own their workflows end to end.

My journey, spanning a quarter-century of industrial procurement and culminating in a capital-market transformation delivered through SAP Signavio, affirms one universal truth: When we automate the trivial, we liberate human ingenuity to tackle the exceptional. In a world where supply disruptions are the new normal, that ingenuity is priceless.

on a weekly basis.