Lean Manufacturing: 5 Core Principles Explained With Examples

Blog Categories:

Published:

July 4, 2023

Reading Time:

7 minutes

How much waste does your company produce? And how much cash is your business losing because of inefficient processes that lead to tons of wastage?

Every year, companies around the world produce millions of tons of waste—yes millions! Well, even though it’s impossible to eliminate waste completely, there surely is a way to minimize it. Introducing lean manufacturing, a decades-old philosophy that many smart and responsible businesses use to this day.

So, what is lean manufacturing? Who started it? And what core principles should you know about? In this article, we’ll answer all these questions, and in the end, discuss the easiest way to get started with lean.

Every year, companies around the world produce millions of tons of waste—yes millions! Well, even though it’s impossible to eliminate waste completely, there surely is a way to minimize it. Introducing lean manufacturing, a decades-old philosophy that many smart and responsible businesses use to this day.

So, what is lean manufacturing? Who started it? And what core principles should you know about? In this article, we’ll answer all these questions, and in the end, discuss the easiest way to get started with lean.

History of Lean Manufacturing

What is lean manufacturing? And why are so many businesses interested in it? Well, simply put, lean manufacturing is a methodology in which the focus lies on minimizing waste and maximizing output. And there’s a reason why companies jumped on this bandwagon.

As we all know, during World War II, Japan faced the destruction that no country has ever faced in the history of mankind. This is why visionary and hardworking Japanese business leaders rolled their sleeves and began the work of reconstructing their industries and economy. The Toyota Production System was created to reduce waste and make employees more productive.

In his detailed system, Taiichi Ohno defined seven types of waste (muda) and created concepts like "Just-in-Time" production and "jidoka" quality control. The lean manufacturing techniques used today are inspired by geniuses like Eiji Toyoda and Taiichi Ohno, who developed the TPS in Japan between 1948 and 1975.

So, since when do we call it “lean manufacturing”? Well, the term "lean" was coined by John Krafcik, an American businessman, in his article "Triumph of the Lean Production System" in 1988. Fast forward to 1996, American researchers James Womack and Daniel Jones defined Lean Manufacturing with five key principles: specifying value, identifying value streams, ensuring uninterrupted value flow, enabling customer pull, and pursuing perfection.

The Birth of Lean Manufacturing in Post-War Japan

It was the end of World War II. The war had ended, but it had left Japan devastated and deficient in resources. Many companies were still in survival mode and were inclined to use raw materials judiciously in order to minimize waste. In post-World War II Japan, Toyota, a company that we all know today, pioneered lean manufacturing. In particular, an engineer who worked for Toyota, called Taiichi Ohno, developed the Toyota Production System (TPS). This would set the foundation for the lean manufacturing principles we use today.As we all know, during World War II, Japan faced the destruction that no country has ever faced in the history of mankind. This is why visionary and hardworking Japanese business leaders rolled their sleeves and began the work of reconstructing their industries and economy. The Toyota Production System was created to reduce waste and make employees more productive.

In his detailed system, Taiichi Ohno defined seven types of waste (muda) and created concepts like "Just-in-Time" production and "jidoka" quality control. The lean manufacturing techniques used today are inspired by geniuses like Eiji Toyoda and Taiichi Ohno, who developed the TPS in Japan between 1948 and 1975.

So, since when do we call it “lean manufacturing”? Well, the term "lean" was coined by John Krafcik, an American businessman, in his article "Triumph of the Lean Production System" in 1988. Fast forward to 1996, American researchers James Womack and Daniel Jones defined Lean Manufacturing with five key principles: specifying value, identifying value streams, ensuring uninterrupted value flow, enabling customer pull, and pursuing perfection.

KEY TAKEAWAYS

- Lean manufacturing originated in post-World War II Japan when companies were finding ways to minimize wastage due to a lack of resources.

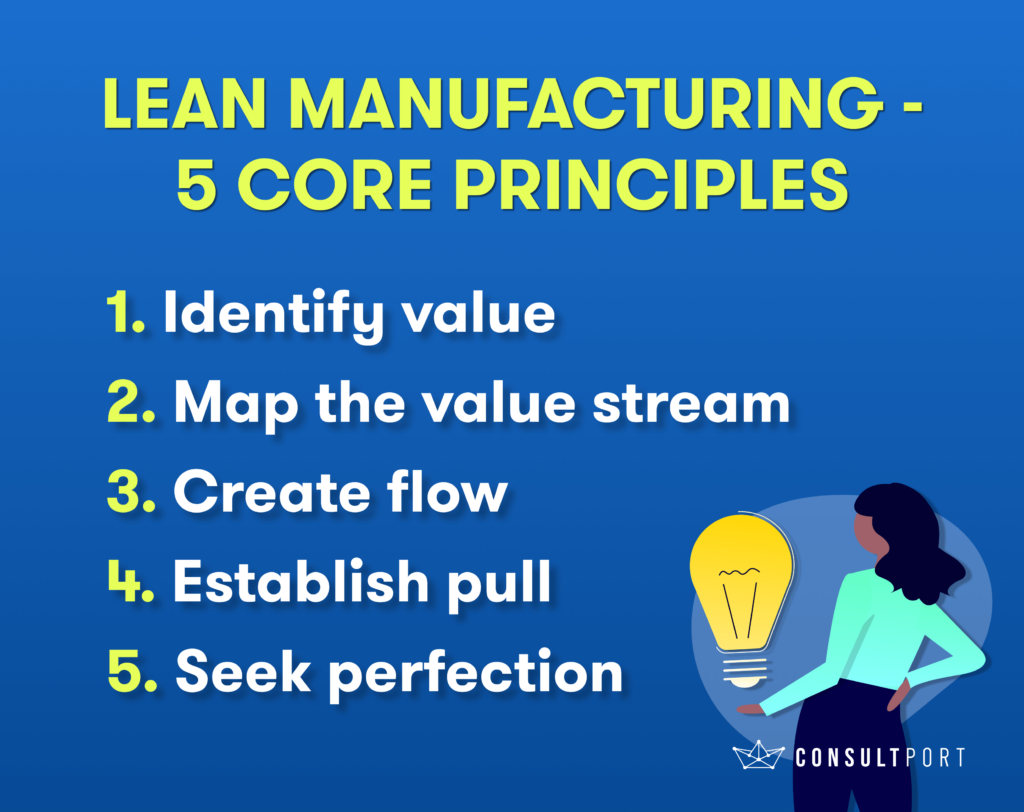

5 Lean Principles You Should Know

Alright, now that you have some background knowledge of lean principles, it’s time to discuss the actual principles. We will discuss how you can use the following principles to decrease waste and maximize profits.

Questions to ask yourself:

Example:

A dietary supplements company finds out that there is a huge target audience of lactose-intolerant people who are protein deficient. So, they launch a lactose-free pea protein drink in four different flavors. By understanding customers’ needs, they are providing value to them in the form of a tasty, refreshing protein drink.

Questions to ask yourself:

Example:

A car manufacturer maps their value stream. They realize that during the assembly process, the batteries that are inserted into cars are manufactured separately and then integrated into the vehicles later. The transportation costs incurred due to this are $30,000 a month. So, the decision maker decides to source batteries from a nearby supplier to reduce the logistics cost to $7000 a month. This decision helps optimize the value stream by minimizing transportation costs and improving overall efficiency.

Questions to ask yourself:

Example:

A toy manufacturing company revamps its production process to create a smooth workflow and increase output. By eliminating bottlenecks and redesigning the production process, they make their workflow more efficient. As a result, they are able to successfully increase the number of toys produced by 20% in just one month. Certainly, this new process will make a lot more kids happy and increase revenue at the same time.

Questions to ask yourself:

Example:

A supermarket creates a pull system to avoid wastage. Using historical data on sales, they are able to accurately forecast the current demand for fruits and vegetables. For example, during data analysis, they find out that the sales of watermelons increase by 25% during summer months while it plummets during winter. They do a similar analysis for other products and create a season-wise chart containing the number of sales of each product. Through this approach, they reduce wastage significantly by not stocking products that are unlikely to sell during a particular season.

Questions to ask yourself:

Example:

A farming equipment manufacturer creates a 4-week training course to teach lean principles to the whole team. Then, they create a general rule under which operational procedures are reviewed every month and suggestions from all employees are considered. By fostering a culture that lives and breathes lean, the company enjoys near-zero wastage and high profits.

1. Identify Value

Identifying value is the first step. It means that you should know what your average customer perceives as valuable. This could include particular features, attributes, or solutions they are willing to pay for. Once you understand what value you’re providing, your processes should align with it accordingly.Questions to ask yourself:

- What features or solutions in particular do customers find valuable?

- How can we step into the customers’ shoes and understand their needs better?

- Which activities assist us in meeting customer needs and creating value?

- What non-valuable activities can we eliminate or reduce?

- How can we differentiate our value proposition from competitors?

Example:

A dietary supplements company finds out that there is a huge target audience of lactose-intolerant people who are protein deficient. So, they launch a lactose-free pea protein drink in four different flavors. By understanding customers’ needs, they are providing value to them in the form of a tasty, refreshing protein drink.

2. Map the value stream

You should know each and every step of your value stream. This includes mapping out every activity that’s undertaken in the value stream: from product creation to delivery. When you create a visual map of the value stream, it helps you identify unnecessary activities that may be wasting raw materials or money.Questions to ask yourself:

- What are all the steps and activities involved in creating and delivering our product?

- How many primary activities and support activities are there in our value chain?

- Are there any delays, bottlenecks, or areas of waste?

- Do we observe any handoffs or unnecessary movement of materials within our workflow?

- Are there opportunities to eliminate or streamline certain process steps to enhance efficiency?

Example:

A car manufacturer maps their value stream. They realize that during the assembly process, the batteries that are inserted into cars are manufactured separately and then integrated into the vehicles later. The transportation costs incurred due to this are $30,000 a month. So, the decision maker decides to source batteries from a nearby supplier to reduce the logistics cost to $7000 a month. This decision helps optimize the value stream by minimizing transportation costs and improving overall efficiency.

3. Create flow

Here’s a simple way to understand flow: do you know how water flows smoothly if there are no obstructions? Similarly, you may create flow in your value stream by eliminating wastage and unnecessary tasks. Furthermore, you can also take steps to streamline value-adding tasks. This can be done by reconsidering the production process, eliminating bottlenecks, and minimizing interruptions in the production process.Questions to ask yourself:

- What measures can we take to ensure a continuous and uninterrupted flow of work?

- Is there a way to automate certain tasks or processes to improve productivity?

- Can the sequence of some activities be rearranged to create a more streamlined workflow?

- How can we identify and address specific obstacles that slow things down?

- Is there a way to cross-train employees and reduce dependencies in the workflow?

Example:

A toy manufacturing company revamps its production process to create a smooth workflow and increase output. By eliminating bottlenecks and redesigning the production process, they make their workflow more efficient. As a result, they are able to successfully increase the number of toys produced by 20% in just one month. Certainly, this new process will make a lot more kids happy and increase revenue at the same time.

4. Establish pull

To understand this, let’s quickly recall what the words “push” and “pull” mean. The word push refers to pressing something in the opposite direction, while pull means drawing something towards oneself. In lean, there’s no room for unnecessarily “pushing” products into the market. This is because there’s no guarantee that customers will buy all products that have been “pushed” into the market. As you may guess, this can cause huge losses and wastage. That’s why a pull approach is incorporated in lean through which products are manufactured when they’re needed.Questions to ask yourself:

- How can we align manufacturing with customer demand?

- Is it possible to implement a just-in-time (JIT) system to avoid overproduction?

- Are we prepared to handle a sudden increase in demand?

- How can we forecast product demand accurately and produce only what we can sell?

- How to minimize inventory levels in order to reduce waste?

Example:

A supermarket creates a pull system to avoid wastage. Using historical data on sales, they are able to accurately forecast the current demand for fruits and vegetables. For example, during data analysis, they find out that the sales of watermelons increase by 25% during summer months while it plummets during winter. They do a similar analysis for other products and create a season-wise chart containing the number of sales of each product. Through this approach, they reduce wastage significantly by not stocking products that are unlikely to sell during a particular season.

5. Seek perfection

Using steps 1-4, you and your team should strive for perfection. Lean is an ongoing way of working and improving. So, every person on the team must know that you’re constantly finding ways to streamline processes, reduce waste, improve product value, and avoid overproduction. Whatever lean steps you take today might not be completely perfect—and that’s fine. It’s not a competition. You just need to keep getting better at using lean principles day by day.Questions to ask yourself:

- What are the best practices or industry standards in our field?

- How can we create an organizational culture where lean is the norm?

- What metrics or benchmarks can we use to measure our progress?

- What methods can we utilize to get feedback from employees from every background?

- Is there a way to create cross-functional teams to enhance collaboration?

Example:

A farming equipment manufacturer creates a 4-week training course to teach lean principles to the whole team. Then, they create a general rule under which operational procedures are reviewed every month and suggestions from all employees are considered. By fostering a culture that lives and breathes lean, the company enjoys near-zero wastage and high profits.

How Lean Manufacturing Consultants Can Help

Are you tired of dealing with inefficiencies and wasted resources in your manufacturing operations? Well, then Consultport has a solution for you: a Lean Manufacturing consultant! Say goodbye to useless bottlenecks and hello to more streamlined processes that can help you meet customer demands in time. Whether it's developing lean manufacturing strategies, optimizing workflows, ideating fresh approaches, or mapping value streams, these consultants can do it all. So, what are you waiting for? Get in touch with us now and let us help you minimize wastage and maximize productivity.

Share This Story, Choose Your Platform!