Remember to fill in all the fields

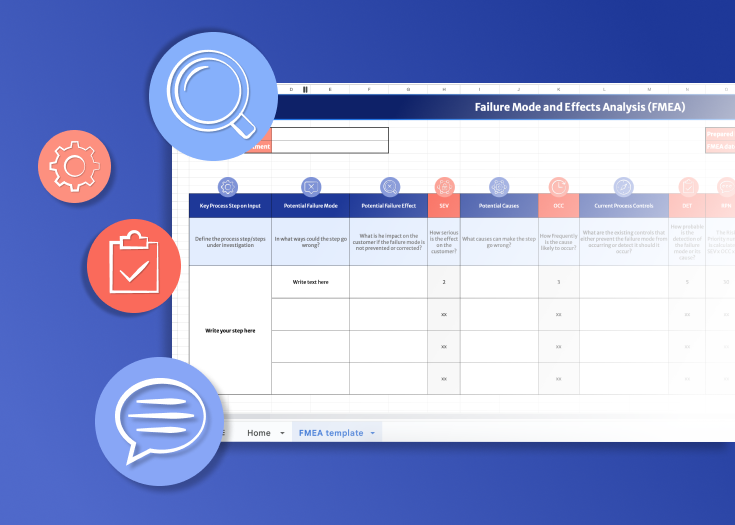

FMEA Template

Join thousands of professionals using this resource

Join thousands of professionals using this resource

- Predict unpleasant consequences in new processes or systems.

- Perfect for improving processes, products, or services.

- Part of the Six Sigma tools. FMEA helps reduce defects, improving quality and profits.

Stand out and make a difference in the new ultra-competitive markets with this free FMEA template.

Ensure the resilience of your company with the remarkable FMEA (Failure Modes and Effects Analysis) model—an invaluable tool designed to identify and prevent quality concerns and financial setbacks during product design and production processes.

By meticulously assessing potential failure scenarios and their consequences, you gain the power to implement preventive measures that guarantee product reliability, safety, and utmost customer contentment. Embrace the FMEA model as your guiding light, paving the way for operational excellence and securing a competitive edge in the market.

Our guides and templates are built to be practical, flexible, and easy to implement. Each resource includes real-world frameworks, best practices, and use cases that you can apply immediately.

Tailored for fast-moving project teams and decision-makers, these guides help you structure and lead initiatives with clarity and confidence.

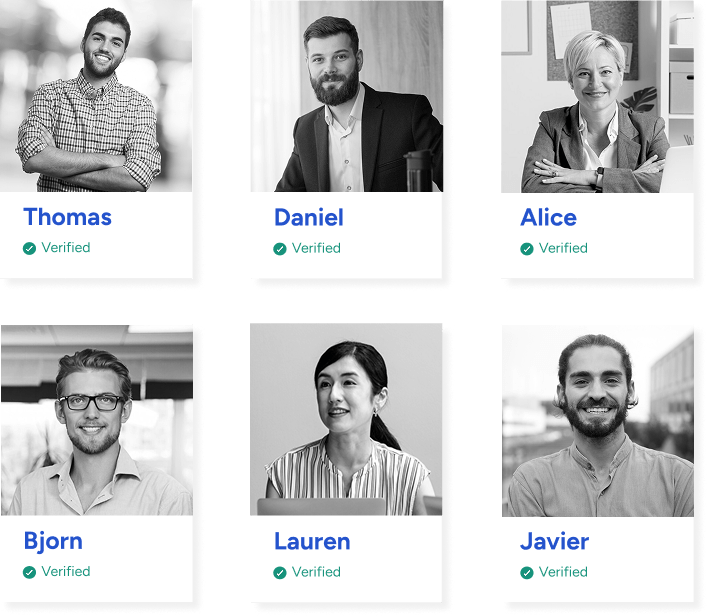

Top-Tier Consultants

These resources are inspired from seasoned freelance consultants from the Consultport network.

Designed to help internal teams and freelance experts work seamlessly together, our tools bring top-tier consulting standards to your business, without starting from scratch.